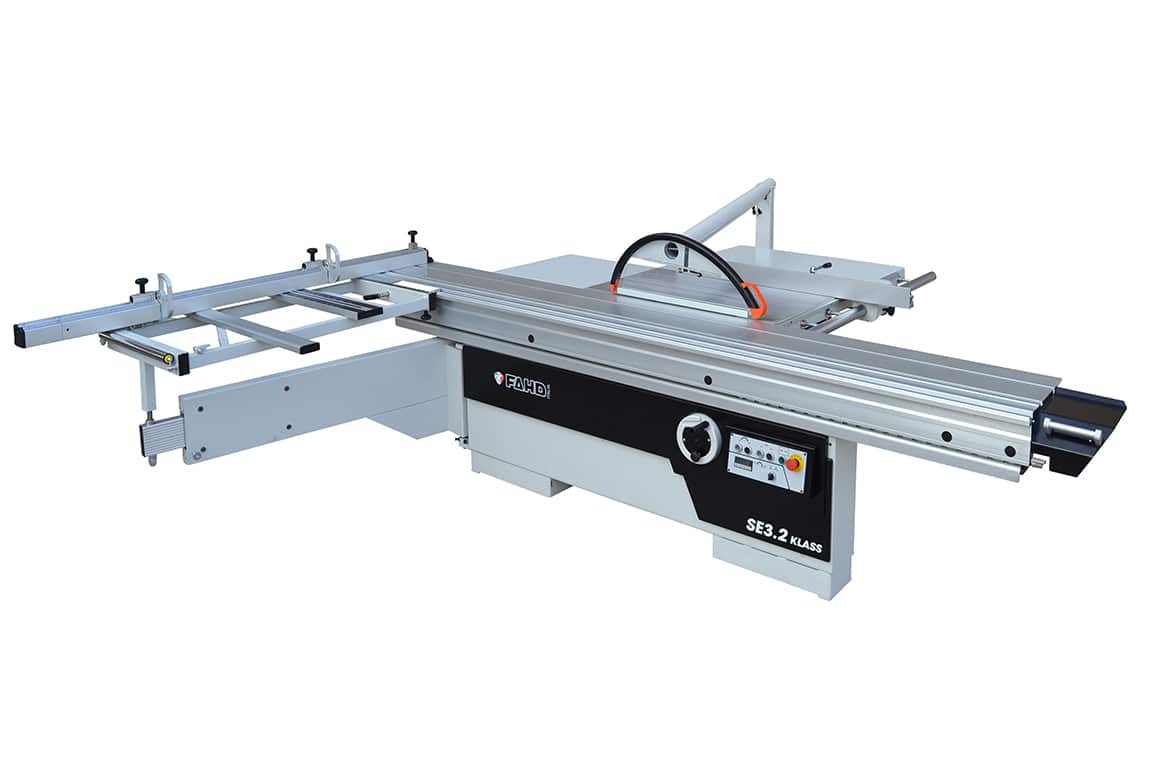

The squaring or circular saw is a cutting tool with movable carriage used in all of the most common woodworking procedures for panels and solid blocks. These tools make it possible to cut timber of any kind and size to obtain highly precise, long and straight cuts.

WHO USES OUR CIRCULAR SAW MACHINES?

As essential bench-top tools for wood cutting, circular saws are intended for use by artisanal and industrial joiner’s workshops working.

WHAT MATERIALS CAN BE CUT WITH INDUSTRIAL CIRCULAR SAW?

Circular saws are born for the cutting of wood, wood panels, solid wood, and other various types. However you can also use them to cut:

- Aluminium and light alloys

- Polystyrene

- Plastic and Insulation Materials

OPERATION AND FEATURES

Wood cutting and squaring machine comprise a base and moving carriage which is quite easy to use: the panel or piece of wood to be cut is placed on the movable surface, so that it meets the blade and the cut can be made at the desired point.

The squaring tool can be requested with manual positioning or automatic positioning (in the digitally controlled version the positioning is managed from a control panel) to facilitate the cutting procedures for the user; a version is also available with optimising software, in which the programme assists the user in cutting the panel with minimum material waste.

CARRIAGE LENGTH

The first aspect to bear in mind when purchasing a squaring tool is the length of the carriage, which does vary from model to model to meet different cutting requirements.

The carriage size of our circular saws ranges from the smallest at 1.600mm to the largest at 3.800mm.

BLADE DIAMETER

The second aspect to take into account is cutting capacity based on the diameter of blade that can be mounted on the circular saw. In this case it will be necessary to provide our technicians with precise information; they will be able to recommend the tool that is best suited to your vertical and/or tilted cutting needs.

CUSTOMIZATION

Most machines support the addition of various accessories upon request and these are already set out for the more advanced models; the following may be included as accessories or personalisation options:

- control panel with internal software for managing fences and positioning

- inverter for managing the blade motor

- motorised parallel fence managed by control panel with brushless motor

- automatic blade lift and tilt

MODELS

Each machine is designed and produced entirely in Italy.

The range of our industrial circular saw machines for cutting of wood includes 5 main lines:

SE Prima line

Dedicated to small artisans, includes 4 machines for small and medium-sized cutting needs

SE Klass line

Dedicated to craftsmen and industry, machinery of medium / large size with increased cutting capacity and engine power.

SE Plus line

Dedicated to craftsmen and industry, machinery of medium / large size, with the possibility of installing the inverter and other electronic systems to manage the cutting process.

SE Evo line

Machines that are born with controlled axis motor and provided with the inverter for the management of the blade speed, suitable for industrial woodworking processing.

SE Pro line

machines that are born with controlled axis motor and provided with the inverter for the management of the blade speed, suitable for industrial woodworking processing. Due to the possibility of installing saw blades till 550mm diameter, this line allows to increase the cutting capability.

SAFETY AND MAINTENANCE

All machines feature is a protection system of the blades in line with regulations. There are also emergency buttons with microswitches to stop the power supply in case of need.

Circular saws for cutting wood do not need any special maintenance operations, if not daily or weekly cleaning of dust, swarf and sawdust.

In support of this activity are the suction nozzles to connect industrial vacuum cleaners, also available in our range.

All information is available in the instruction booklet together with your purchase.

WARRANTY

All FAHDITALIA products are guaranteed against defects in materials and workmanship under normal use and maintenance conditions. The warranty period is 12 months from the date of purchase.

We also offer a warranty of 10 years for the sliding table.

INSTALLATION

The installation service offered by the company is carried out by specialized dealers, present over most of the territory, both nationally and internationally.

Ask for information

If you want a quote, you are looking for a custom machine or you simply need a recommendation for purchase, leave us your contact details together with your message and we will contact you within 48 H!